Static Eliminator – Static electricity is a problem faced all over the world. It can affect most industries which handle non-conductive materials such as plastics, paper, board, laminates and textiles. Electrostatic attraction or repulsion causes materials to stick to machinery, or to each other, causing jams, slow machine speeds and reduced quality and productivity. Friction, pressure and separation are the major causes of static electricity.

Product Description

STATIC ELIMINATOR MANUFACTURERS INDIA

Static Eliminator – Static electricity is a problem faced all over the world. It can affect most industries which handle non-conductive materials such as plastics, paper, board, laminates and textiles. Electrostatic attraction or repulsion causes materials to stick to machinery, or to each other, causing jams, slow machine speeds and reduced quality and productivity. Friction, pressure and separation are the major causes of static electricity.

When humidity is low, higher static charges are generated .Static becomes more noticeable during winter season, when the air normally dry.

Problems caused by static electricity are:

|

Remedy to the above Problems

To prevent the above one has to either neutralize the static charge or it should be conducted away to the ground.

How Static Charge Eliminator Works

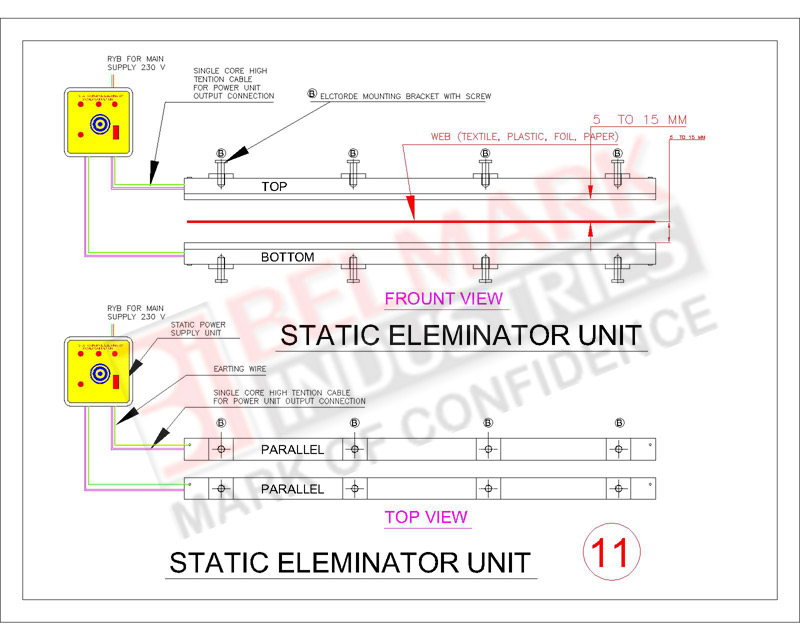

Eliminator bars which are fixed as near as possible to the material process, on getting supply from the control unit, ionize the surrounding air and because of this, static electric charge is conducted away to the ground.

How Static Charge Eliminator Works

Eliminator bars which are fixed as near as possible to the material process, on getting supply from the control unit, ionize the surrounding air and because of this, static electric charge is conducted away to the ground.

Static Eliminator Drawings

Applications

|

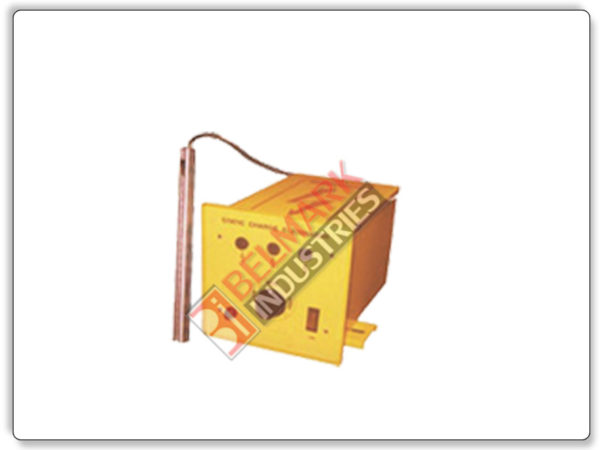

Power Unit

Power Control Unit – Can connect upto 3 Nos. Static bars of upto 120 inches working width in the following way:-

Top of Film and bottom of film in parallel (Top and bottom side of film) for entry level and one No. bar for end side is necessary.

One Control Power unit have provision for connecting three static bar connections. One No. extra spare card is provided inside, so that any one of the connection fails during simultaneous use of all the three, the spare card can be used. After disconnecting the power unit, manually change the static cord from the failed card connection to the spare card connection. To do this, simply open the top cover of the Control Power Unit and change the static cord connection from failed card to the spare card.

The power unit comes with one meter length 3 core power cord and static bars comes with two meter single core high power meters special cables as standard length.